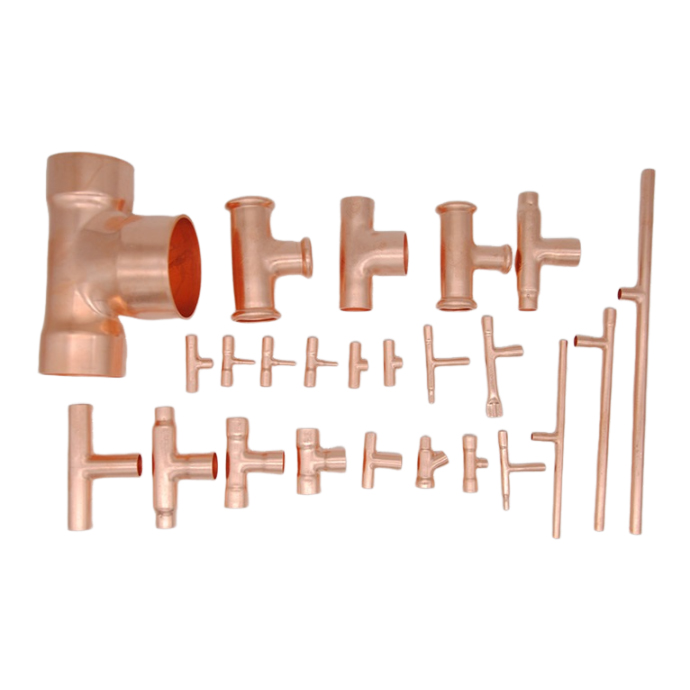

많은 사람들이 일반 티 피팅 대신 구리 감소 티 피팅을 선택하는 이유는 무엇입니까?

2025-04-14In the design of piping systems, tees are key components for flow diversion or confluence, and Copper Reducing Tee Fitting have unique advantages over Ordinary Tee Fittings.

1. More accurate flow and pressure regulation.

Ordinary Tee Fitting is only suitable for scenarios with the same pipe diameter, while Copper Reducing Tee Fitting can achieve precise control of flow and pressure through variable diameter design.

2. Optimize flow distribution.

For example, in the water supply system, the main pipe is distributed to different levels through Copper Reducing Tee Fitting to avoid the problem of too high water pressure in the low layer and insufficient water pressure in the high layer.

3. Reduce turbulence and energy loss.

The tapered design of Copper Reducing Tee Fitting can reduce the vortex caused by fluid mutation and reduce pressure loss, while Ordinary Tee Fitting is prone to turbulence in variable diameter system.

4. Adapt to complex pipeline system.

When more pipes are needed, Ordinary Tee Fitting need to add additional reducers when the pipe diameters are inconsistent, while Copper Reducing Tee Fitting directly integrate the reducer function to reduce the number of connection points.

5. More flexible spatial layout.

In a small space, Copper Reducing Tee Fitting can reduce pipe stacking and simplify installation.

6. Low maintenance cost.

Ordinary Tee Fitting are prone to leakage due to multiple interfaces, but Copper Reducing Tee Fitting have a more stable structure and stronger long-term reliability.

Therefore, Copper Reducing Tee Fitting have significant advantages in reducing diameter requirements, system stability, and flexibility, and are ideal for complex pipeline systems, while Ordinary Tee Fitting are only suitable for simple equal-diameter diversion scenarios.